Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: BZJ1450 | Place of Origin: China |

CANGZHOU OUGUAN PACKING MACHINERY CO.,LTD

ADD: ZHUWA VILLAGE, LIANZHEN TOWN, DONGGUANG COUNTY, CANGZHOU CITY, HEBEI PROVINCE

TEL: 0086-0317-7810952 FAX: 0086-0317-7810952

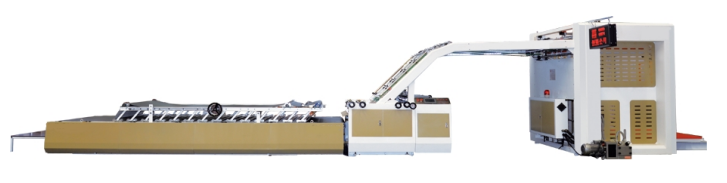

Automatic flute laminator machine

Product Features

Suitable for 150-600 grams of cardboard and corrugated paper

The whole machine adopts plc system and dual inverter control mode, and has high stability.

The bottom paper adopts vacuum adsorption paper feeding; the facial paper adopts positive humanized paper feeding, saving time and effort

The spare stacking paper table can be used to pile up the next stack of paper in the non-stop state, and push the elevator into the lifting platform along the guide rail, which has high working efficiency; when the lifting platform is pushed into the lifting platform, the pre-stack can be returned, labor saving;

The pressing part adopts a floating movable structure with a total length of 5 meters and 28 paper-pressing shafts, so that the cardboard is evenly stressed during the flattening process.

Automatic glue replenishment system, automatic recycling of glue, scientific design of rubberized shaft and rubber shaft, calculation of drum line speed difference, avoiding high-speed rotation of glue while uniformly coating

The bottom shaft passive rubber shaft is squeezed and cleaned to clean the bottom pressure shaft to ensure the back of the bottom paper is cleaned, and the foreign matter such as the glue is directly deposited into the water tank. At the same time, the rack and pinion method is used to control the lifting and lowering of the water tank, and the water tank can be easily taken out for convenient cleaning.

The machine runs fast, the paper feeding is easy, the operation is smooth and accurate; the pressure adjustment adopts the unilateral adjustment of the pressure of each pressure roller, and is equipped with a pressure scale display, and the specification of the replacement paper is adjusted in one step.

Introduction:

◆The vacuum suction-type feeding system can lead the paper accurately into the machine;cycle stacking planes in a state of non-stop the next batch of paper stack well, so that more efficient.

◆Using suction feeding automatic of bottom sheet, according to the main machine operating speed, continuous automatic tracking.

◆The machine operation is stable, surface paper with corrugated paper joint very Accurate. The corrugated paper never pull ahead, surface paper's location is easy adjust.

◆The new concept is flexible front lay position, the positioning accuracy is high, and the bottom paper never advances.

◆Machine uses touch-screen/PLC/servo motor control system, the circuit system is stable, and can automatically display the failure alarm.

◆Automatic gluing, and the glue can be used circulatory, avoid glue waste.

◆Roller design scientifically, avoid glue fly out when the speed is high.

◆Pressure rollers adopt unilateral adjustment, convenient and fast.

◆Rocker controls wash roller's fluctuation, easy cleaning.

◆Counter designs scientifically, easy recording the amount you have been worked.

Technological parameter

|

Model |

1450 |

|

Max laminating size |

1400mm×1250mm |

|

Min laminating size |

400mm×400mm |

|

Economic speed |

0-100/min |

|

Laminating precision |

±1.5 |

|

Power |

12kw |

|

Size |

13.5m×2.05m×2.4m |

|

Weight |

About 5t |

|

bottom paper thickness |

A/B/C/E 3/4/5 12mm |

|

surface paper thickness |

150-600gsm |

|

Display screen |

Delta (Taiwan) |

|

Switching power supply |

OMRON |

|

Mainframe Motor |

Tianjin Tong'de'li |

|

Feeder |

Japanese Rigung |

|

Geared motors |

Shanghai Renmin |

|

Vacuum pump |

EUROVAC (Taiwan) |

|

Vortex Pump |

Shanghai Hengli |

|

Synchronous belt |

Ningbo Beidi(Joint venture) |

|

Bearing |

WTJB,HRB,LYC |

|

The host chain |

CHOHO (sino-JapaneseJoint venture) |

|

Transfer press belt |

Italy(Joint venture) |

|

PLC |

Panasonic(Japanese) |

|

Contactor |

SCHNEIDER(The French) |

|

The host inverter |

Delta (Taiwan) |

|

Pressure platform inverter |

Delta (Taiwan) |

|

Pressure platform motor |

Shanghai oute |

1. Feeder system:

High-precision high-speed Feida paper feeding, smooth and smooth paper feeding.

Reinforced paper feeding device, the nozzle angle can be adjusted freely, adapt to different types of facial tissue

2. Electrical component:

The main electrical components use imported brands

PLC tracking technology, automatic fault detection

3. Pressure regulation system:

Uniform pressure adjustment ensures consistent pressure on both sides

Pressure scale display shows easy adjustment when changing paper specifications

4. Pressure and output system:

Floating flat design eliminates the need to adjust press pressure

Heightening design, which is conducive to the smooth work of thick corrugated cardboard

![]()